- Powder Handling System

- Solvent Handling System

- Slurry Handling System

- Mixing System

- Coating System

- Calendering System

- Slitting System

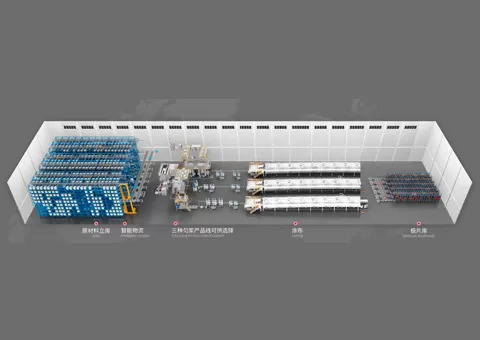

- Automated Warehouse Management Systems and Solutions

- Industrial Automated Material Handling and Storage Systems

- RFID Solution for Warehouse and Inventory Management System

- Intelligent Central Control System

- Raw Material Handling System

- Kiln Sintering Device

- Energy Mill System

- Blending System

- Auto-Packing System

- Automated Warehouse Management Systems and Solutions

- Industrial Automated Material Handling and Storage Systems

- RFID Solution for Warehouse and Inventory Management System

- Intelligent Central Control System

Warning: Illegal string offset 'id' in /repo1/WebsiteBuildingSystem_v2024/librarys/Suco/View.php(276) : eval()'d code on line 477

- Manually Small Bag Breaker

- Centralized Storage, Dust Removal, Iron Removal System of Powder

- Small Bag Automatic Suction Machine

- Automatic Suction System of Big Bag

- Automatic Small-Bag Unpacking Machine

- Automatic Big-Bag Unpacking Machine

- Normal Unpacking Type of Big Bag

- Viscous Material High Accuracy Weighing Soft Scale Hopper

- Double-layer Pipe Design

- Double-layer Pipe of Gravity Blanking

- Automatic Magnetic Filter

- Flash Drying+Rotary Kiln Roaster+Cooling Conveying System

- 6-Tube Nitrogen Roller Furnace

- Gas-Electric Hybrid Roller Kiln

- Six-Tube Double-Layer Double-Cavity Nitrogen Roller Furnace

- 4/6 Air and Oxygen Roller Furnace

- 4-Row Nitrogen Roller Furnace for Anode

- Laboratory Box Chamber Furnace

- Nitrogen Closed-Loop Pneumatic Conveying System

- Dilute Phase Pneumatic Conveying System

- Dense Phase Pneumatic Conveying

- Negative Pressure Pneumatic Conveying System

- Key Equipment for Pneumatic Conveying System

- Baked Food Raw Material Batching System

- Instant Noodle Raw Material Batching System

- Solid Beverage Raw Material Batching System

- API Raw Material Batching System

- Auxiliary Material Automatic Batching System

- Positive Pressure Dilute Phase Conveying

- Negative Pressure Dilute Phase Conveying

- Dense Phase of Rotary Valve

- Dense Phase of Blowing Tank

- Intelligent Adjustable Air Control Unit

- Silo

- Weighing and Batching Device

- Dust Removal and Impurity Removal System

- Automatic Small-Bag Unpacking Machine

- Automatic Big-Bag Unpacking Machine

- Normal Unpacking Type of Big Bag

- Automatic Suction System of Big Bag

- Small Bag Automatic Suction Machine

What are you looking for?

English

English  中文

中文