Chemical production involves a wide variety of raw materials, ranging from fine powder chemicals such as various catalysts and additives, to granular materials like plastic resins and fertilizers. These materials come in various packaging forms, including standard woven bags and bulk ton bags, and some may be toxic, corrosive, flammable, or explosive. Traditional manual unpacking methods suffer from low efficiency, high labor intensity, significant safety risks, and issues such as material loss and environmental contamination, making them inadequate for the demands of modern chemical manufacturing.

Working Principle of Automatic Unpacking Machine

Automatic bag unpacking machines use mechanical systems to perform automatic bag feeding, positioning, cutting, and material discharge. Common methods for bag opening include blade cutting and serrated tearing. Once the bag is opened, the material falls—either by gravity or via a conveying system—into subsequent processing equipment. The entire process occurs in an enclosed environment, which effectively reduces dust leakage.

Types of Automatic Unpacking Machine

Small-Bag Automatic Unpacking Machine

These are suitable for materials packaged in 5–50 kg bags. The machine automatically grabs and conveys the bags to the cutting station, where a blade or other mechanism opens the bag. The contents then fall into a hopper or conveying system by gravity. For example, when processing chemical additives, a small-bag unpacking machine can quickly and accurately complete the unpacking task, handling hundreds of bags per hour.

Ton-Bag Automatic Unpacking Machine

Designed for bulk packaging of around one ton. The ton bag is first lifted to a designated height, where a mechanical system either opens the bag spout or cuts it open. The material is discharged by gravity, often assisted by vibration. In plastic pellet manufacturing, ton-bag unpacking machine enable continuous, automated bag unloading system, significantly boosting production efficiency.

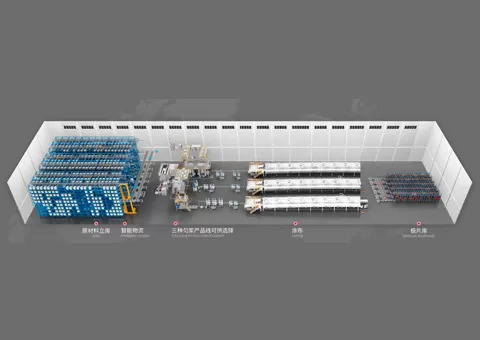

Application Scenarios in the Chemical Industry

Raw Material Feeding

In chemical production plants, automatic unpacking machine open various raw material packages and directly feed the contents into reactors or batching systems. For instance, in paint manufacturing, bags of resin and pigment are unpacked automatically and the contents proportionally conveyed to the mixing equipment, ensuring accurate and timely raw material addition. This improves both production efficiency and product quality consistency.

Material Transfer and Storage

In chemical warehouses, when materials need to be transferred to other production stages or undergo secondary processing, automatic unpacking machine can quickly complete the unpacking process. This minimizes delays during transfer and prevents production interruptions due to slow manual unpacking. For example, in fertilizer plants, stored bulk fertilizer can be rapidly unpacked and delivered to the production line, maintaining continuous operation.

Waste Disposal

Automatic unpacking machine can also be used to clean residual materials from packaging waste generated during chemical production, facilitating recycling or proper disposal of the bags. For instance, in pesticide manufacturing, used pesticide bags can be automatically unpacked to recover residual chemicals, reducing environmental pollution and enabling resource reuse.

Advantages of Using Automatic Unpacking Machine in the Chemical Industry

Increased Production Efficiency

Automatic machines unpack far more quickly than manual labor and can operate continuously, significantly shortening production cycles. At a large chemical plant, the introduction of automatic unpacking machine increased unpacking efficiency by over five times and boosted overall production capacity by 20%.

Enhanced Worker Safety

By eliminating direct contact with toxic, hazardous, or flammable materials, automatic unpacking reduces the risk of poisoning, burns, or explosions. For example, when handling chemical materials containing heavy metals, the machine protects workers from exposure, ensuring their safety.

Reduced Material Waste and Pollution

The automated process is precise and controlled, leaving minimal residue and reducing material waste. The enclosed system also prevents dust from spreading and avoids cross-contamination, meeting environmental standards. In pharmaceutical chemical production, for instance, the use of automatic unpacking machine has reduced material loss rates to below 1% and significantly lowered dust levels in the workspace.

Lower Labor Costs

A single automatic unpacking machine can replace the workload of multiple workers, cutting costs associated with recruitment, training, and management. As labor costs continue to rise, this represents significant savings for companies. For example, a mid-sized chemical enterprise saved several million yuan annually in labor expenses after implementing automatic unpacking machine.

English

English  中文

中文